DISCS STACK SEPARATORS

Centrifugal separators are intended for mechanical separation of solid-liquid or solid-liquid-liquid suspensions. Separators are widely used in olive oil, dairy products, food and beverage production, juice production, oil refining and oil recovery. The separators consist of the bowl group rotating at high speed, the drive mechanism that moves the bowl group and a frame construction carrying these elements. HAUS separators ensure the continuous and rapid removal of solids during the process of separation of the feed product into phases.

HAUS separators ensure that solid particles are removed from the bowl group by discharging unwanted solid particles quickly and without interrupting the product feed during the process of separation of the feed product into phases. Thanks to its high centrifugal force and fast discharge systems, it saves time and energy.

Minimum particle size that can be separated is directly related to the viscosity of the fluid, density difference between phases, capacity and the design of the selected separator. Based on its extensive process knowledge and experience, HAUS provides the most suitable separator model for its customers. This enables solid particle separation up to 1 μm in specific processes.

Centrifugal separators are intended for mechanical separation of solid-liquid or solid-liquid-liquid suspensions. Separators are widely used in olive oil, dairy products, food and beverage production, juice production, oil refining and oil recovery. The separators consist of the bowl group rotating at high speed, the drive mechanism that moves the bowl group and a frame construction carrying these elements. HAUS separators ensure the continuous and rapid removal of solids during the process of separation of the feed product into phases.

HAUS separators ensure that solid particles are removed from the bowl group by discharging unwanted solid particles quickly and without interrupting the product feed during the process of separation of the feed product into phases. Thanks to its high centrifugal force and fast discharge systems, it saves time and energy.

Minimum particle size that can be separated is directly related to the viscosity of the fluid, density difference between phases, capacity and the design of the selected separator. Based on its extensive process knowledge and experience, HAUS provides the most suitable separator model for its customers. This enables solid particle separation up to 1 μm in specific processes.

Separators can be classified into three different configurations as purifiers, concentrators and clarifiers according to their application areas. Clarifiers provide cleaning of unwanted solids and obtaining a clean and sediment-free product by separating solid-liquid mixtures, while minimizing the need and costs of filtration in the processes where filtration is compulsory. Purifiers are designed to separate liquid-liquid mixtures, while concentrators are designed to separate liquid-liquid mixtures from each other and to adjust the concentration of the light phase to the desired value. Purifiers and concentrators provide high efficiency separation and are effective in solid particle cleaning. According to your needs; there are manual separators that can be easily removed and cleaned manually and automatic discharge separators which remove unwanted solids out of the bowl quickly and effectively without interrupting the product supply.

HAUS separators have high separation efficiency, quiet operation, low power consumption, easy operation, high hygiene and superior material quality. Operating parameters (solid discharge frequency, etc.) can be easily changed with the touch screen panel on the separator panel and can be easily integrated to fully automated plants. The materials used in HAUS separators are selected according to the requirements of the sector for which they are designed and international standards. HAUS separators incorporate the latest innovations in separation technologies. HAUS separators provides process-based properties such as cleaning in place(CIP) system, high temperature resistance, erosion protection, corrosion resistance. Separator accesory equipment and piping connections can be changed as desired. HAUS Centrifuge Technologies has a separation solution that meets your needs under any circumstances thanks to flexible project-based works and customizable separation solutions.

WORKING PRINCIPLE

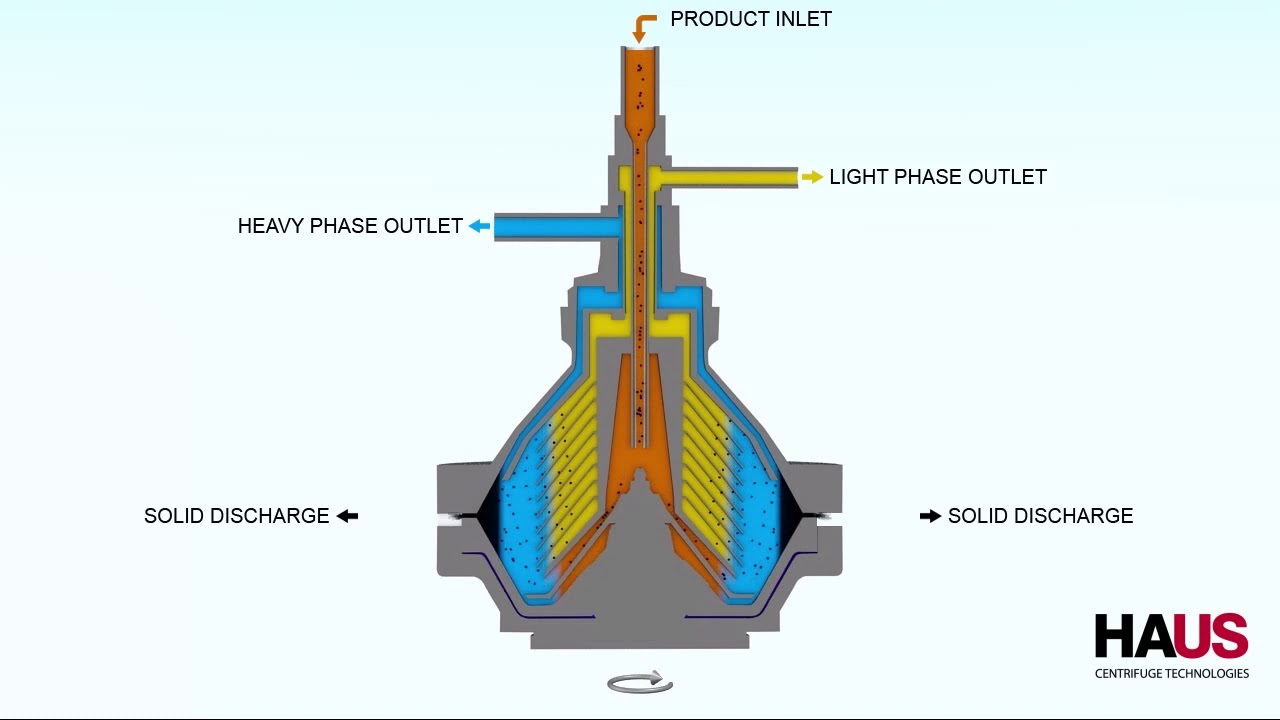

The product mixture is introduced into the bowl, where it is put into rotation. The centrifugal force results in the product mixture being separated according to density differences. The product is forced to flow through tiny spaced discs, which allows the heavy phase and the light phase to flow in opposite directions. The heavy phase overflows from the periphery through the heavy phase paring disc* (centripetal pump) depending on separator type to exit under pressure. The light phase flows in the center through the light phase paring disc*, depending on separator type also exiting under pressure. The counter-pressure valves on the outlet pipes can be adjusted to regulate the interphase inside the bowl.

Heavier solid particles accumulate in the in the sludge volume of bowl periphery, from where they are discharged periodically. During partial discharge operation, only the sludge volume is emptied. Differently, the total discharge operation empties the entire bowl volume. Any sequence of partial and total discharge can be programmed into the PLC via the HMI interface, such that it is carried over by the automatic control system.

* It may vary depending on separator model (free flow / centrifugal pump)

Separators can be classified into three different configurations as purifiers, concentrators and clarifiers according to their application areas. Clarifiers provide cleaning of unwanted solids and obtaining a clean and sediment-free product by separating solid-liquid mixtures, while minimizing the need and costs of filtration in the processes where filtration is compulsory. Purifiers are designed to separate liquid-liquid mixtures, while concentrators are designed to separate liquid-liquid mixtures from each other and to adjust the concentration of the light phase to the desired value. Purifiers and concentrators provide high efficiency separation and are effective in solid particle cleaning. According to your needs; there are manual separators that can be easily removed and cleaned manually and automatic discharge separators which remove unwanted solids out of the bowl quickly and effectively without interrupting the product supply.

HAUS separators have high separation efficiency, quiet operation, low power consumption, easy operation, high hygiene and superior material quality. Operating parameters (solid discharge frequency, etc.) can be easily changed with the touch screen panel on the separator panel and can be easily integrated to fully automated plants. The materials used in HAUS separators are selected according to the requirements of the sector for which they are designed and international standards. HAUS separators incorporate the latest innovations in separation technologies. HAUS separators provides process-based properties such as cleaning in place(CIP) system, high temperature resistance, erosion protection, corrosion resistance. Separator accesory equipment and piping connections can be changed as desired. HAUS Centrifuge Technologies has a separation solution that meets your needs under any circumstances thanks to flexible project-based works and customizable separation solutions.

High separation efficiency

High quality material

Low noise and vibration

Easy control of the working parameters by using HMI and PLC

Fast and effective solid discharges

Drive systems with low power consumption

High hygiene and ready for cleaning in place(CIP)

Flexible project-based separation solutions

WORKING PRINCIPLE

The product mixture is introduced into the bowl, where it is put into rotation. The centrifugal force results in the product mixture being separated according to density differences. The product is forced to flow through tiny spaced discs, which allows the heavy phase and the light phase to flow in opposite directions. The heavy phase overflows from the periphery through the heavy phase paring disc* (centripetal pump) depending on separator type to exit under pressure. The light phase flows in the center through the light phase paring disc*, depending on separator type also exiting under pressure. The counter-pressure valves on the outlet pipes can be adjusted to regulate the interphase inside the bowl.

Heavier solid particles accumulate in the in the sludge volume of bowl periphery, from where they are discharged periodically. During partial discharge operation, only the sludge volume is emptied. Differently, the total discharge operation empties the entire bowl volume. Any sequence of partial and total discharge can be programmed into the PLC via the HMI interface, such that it is carried over by the automatic control system.

* It may vary depending on separator model (free flow / centrifugal pump)

PRODUCT SERIES

You May Also Be Interested

HAUS

How Can We Help You?

#BECAUSEWECARE